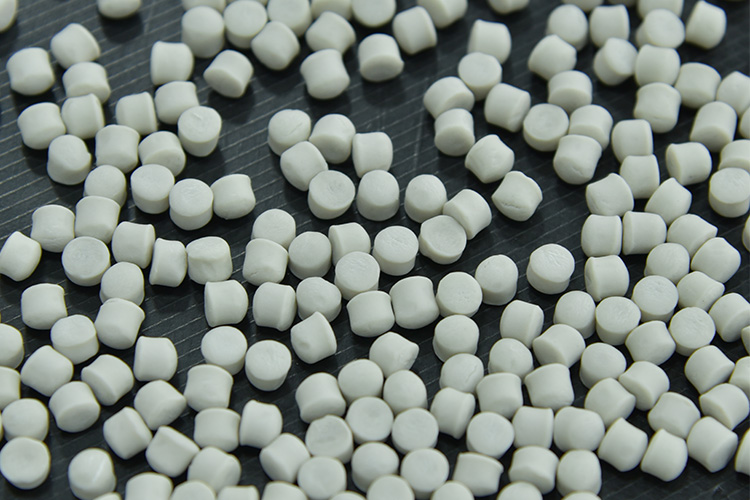

Role of the rubber accelerator DPG(D)

- Mingpai

- 2024-06-07 11:21:57

DPG, or Diphenylguanidine, is a crucial accelerator in the rubber industry, belonging to the class of guanidine-based accelerators. It plays several significant roles in the vulcanization process of rubber compounds, contributing to the optimization of both processing and final product characteristics. Here's a closer look at the key roles of DPG as a rubber accelerator:

Acceleration of Vulcanization: DPG acts as a primary accelerator, facilitating the cross-linking reactions between rubber molecules and sulfur during vulcanization. It donates nitrogen to form cross-links, which are essential for transforming the uncured rubber from a plastic state into a resilient elastomer.

Increased Crosslink Density: By promoting efficient sulfur utilization, DPG helps increase the number of cross-links formed within the rubber matrix. This results in a higher crosslink density, which translates to improved physical properties such as enhanced tensile strength, modulus, and hardness of the vulcanizate.

Fast Cure Rate: DPG accelerates the vulcanization process, leading to shorter curing times. This characteristic is beneficial for high-volume production where rapid cycle times are critical to efficiency and cost-effectiveness.

Synergistic Effects: When used in combination with other accelerators, DPG can exhibit synergistic effects, enhancing the overall efficiency of the vulcanization system. It is often paired with thiuram or sulfenamide accelerators to balance cure rate, scorch time, and improve the dispersion of sulfur in the rubber compound.

Impact on Processing: Despite its effectiveness in accelerating vulcanization, DPG does not offer the same level of scorch protection as some other accelerators, like sulfenamides. Therefore, its use requires careful monitoring during the mixing and processing stages to prevent premature vulcanization or scorching, especially in warmer environments or with long mixing cycles.

Influence on Physical Properties: While DPG can enhance certain physical properties like modulus and resilience, its use may also result in increased hysteresis and heat build-up in rubber products, which could be detrimental in applications where low heat generation is desired.

Compatibility: DPG is compatible with a wide range of rubber types, including natural rubber (NR), styrene-butadiene rubber (SBR), and butadiene rubber (BR), making it a versatile accelerator across different rubber formulations.

In summary, DPG plays a central role in optimizing the vulcanization process by accelerating cross-link formation, increasing crosslink density, and potentially enhancing certain physical properties of the rubber compound. Its use demands careful management to balance rapid curing with the risk of scorching and to consider its impact on the final product's performance characteristics.