What are the accelerators for rubber vulcanization pre- and post-cure?

- Mingpai

- 2024-07-08 15:23:06

In the rubber vulcanization process, the selection of accelerators plays a vital role in managing the pre-effect (early-stage activity) and post-effect (delayed acceleration). Here are typical accelerators associated with each effect:

Pre-Effect Accelerators (Fast Initial Activity):

Although direct categorization as "pre-effect" accelerators is less common, certain accelerators known for their swift activation of the vulcanization system can be considered. For instance, Thiazoles (like Accelerator M, DM) are characterized by their rapid initiation of the curing process in the early stages.

Post-Effect Accelerators (Delayed Acceleration Characteristics):

Post-effect accelerators exhibit lower initial activity, offering a prolonged scorch safety time and increasing their effectiveness as the vulcanization proceeds. Key representatives include:

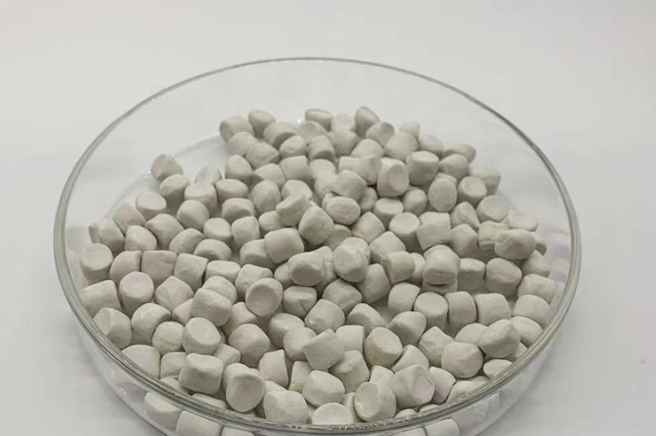

Sulfenamides (such as CZ, NS, DZ, NOBS): These are archetypes of post-effect accelerators, known for their long scorch times, high curing activity, and the provision of a favorable vulcanization plateau, making them ideal for applications requiring meticulous control over the curing process.

Thiurams (while not strictly classified as post-effect, specific thiuram derivatives can be adjusted within formulations to contribute to a delayed action profile, affecting the overall vulcanization characteristics).

Sulfur donors, such as dithiocarbamates and certain sulfur-containing compounds, can also show post-effect behavior when formulated strategically.

When selecting accelerators, considerations include the type of rubber (natural rubber, SBR, BR, etc.), product requirements (physical properties, aging resistance), and manufacturing processes (molding methods, curing conditions). A judicious combination of different accelerator types enables precise control over both the pre-effect and post-effect phases, leading to optimized vulcanization outcomes and superior product performance.