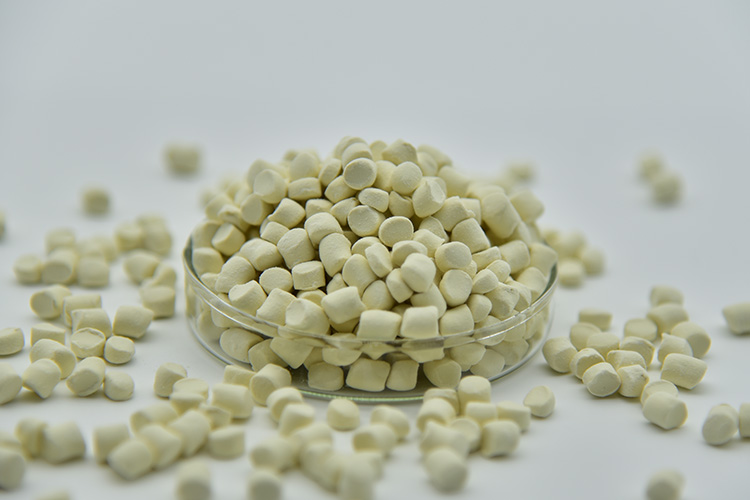

Role of the rubber accelerator MBT(M)

- Mingpai

- 2024-06-07 11:37:44

MBT(M), which is commonly referred to as simply MBT (Mercaptobenzothiazole) in the rubber industry, is a widely used accelerator in sulfur vulcanization processes. It plays a crucial role in the manufacturing of rubber products by influencing both the vulcanization process and the final product's properties. Here's a detailed explanation of the roles MBT(M) fulfills:

Vulcanization Acceleration: MBT acts as a primary accelerator, promoting the cross-linking of rubber molecules during vulcanization. Its mercaptan group (-SH) reacts with sulfur to form bridges between rubber polymer chains, expediting the curing process and ensuring a more complete and efficient vulcanization. This results in shorter curing times and enhanced processing efficiency.

Enhancement of Physical Properties: MBT contributes to the improvement of the physical properties of vulcanized rubber, such as tensile strength, modulus, and abrasion resistance, without significantly affecting the elasticity of the rubber. It helps create a well-balanced combination of hardness and flexibility, which is crucial for many rubber applications.

Moderate Scorch Resistance: While not the most effective in terms of scorch resistance compared to some specialized accelerators, MBT still provides a moderate level of protection against premature vulcanization (scorching) during the mixing and processing stages. This is beneficial for controlling the processing window and avoiding wastage due to over-curing before shaping or molding.

Compatibility with a Wide Range of Rubbers: MBT is compatible with various types of rubber, including natural rubber (NR), styrene-butadiene rubber (SBR), butadiene rubber (BR), and nitrile rubber (NBR), among others. This versatility makes it a common choice for a wide array of rubber goods, from tires to industrial components and consumer products.

Synergistic Effects: MBT often works in conjunction with other accelerators, activators, and sulfur donors to create a synergistic effect that optimizes the vulcanization process. For example, combining MBT with accelerators like zinc dibutyl dithiocarbamate (ZDBC) or using it along with sulfur and zinc oxide can enhance cure rates, improve dispersion, and tailor the final product's properties to specific application needs.

Economic Benefits: MBT is considered cost-effective compared to some high-performance accelerators, making it an economically viable choice for many rubber manufacturers without compromising on the required quality and performance standards.

Environmental and Safety Considerations: As with any chemical used in industrial processes, MBT requires careful handling due to its potential health and environmental implications. Appropriate protective measures should be taken during storage, handling, and disposal to minimize risks to workers and the environment. Efforts are also being made to develop and implement safer alternatives or processes to reduce these concerns.

In conclusion, MBT(M) is a fundamental accelerator in rubber technology, playing a pivotal role in accelerating vulcanization, enhancing the physical properties of rubber products, and ensuring compatibility with a broad range of rubber types. Its ability to work synergistically with other chemicals and provide a balance between performance and economy underscores its importance in rubber manufacturing processes.