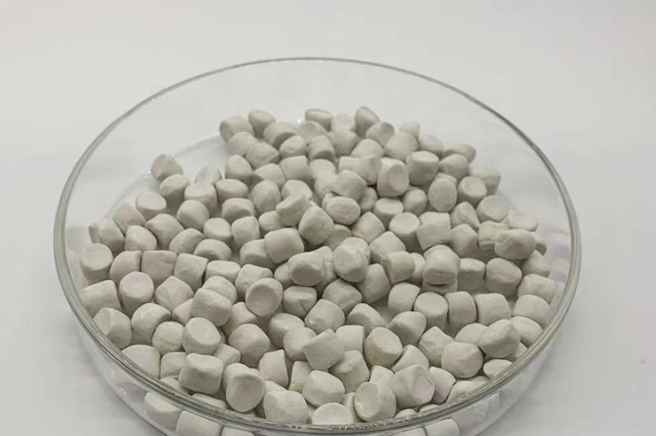

Role of the rubber accelerator TMTD(TT)

- Mingpai

- 2024-06-07 12:03:38

TMTD(TT), also known as Tetramethylthiuram Disulfide or Thiuram Disulfide, is a significant accelerator in the rubber industry, widely utilized in sulfur vulcanization processes. It plays a multifaceted role in enhancing the efficiency of rubber compound processing and the properties of the final vulcanized rubber products. Here's a comprehensive look at the roles of TMTD(TT):

Efficient Vulcanization Acceleration: TMTD(TT) is a powerful accelerator that accelerates the sulfur vulcanization process by releasing sulfur and other active species upon thermal decomposition. This accelerates the cross-linking of rubber molecules, promoting faster and more efficient curing, leading to shorter cycle times and increased productivity.

Scorch Resistance: TMTD(TT) offers good scorch resistance, delaying the onset of premature vulcanization during mixing and storage. This feature is especially valuable for rubber compounds that require long mixing times or are processed at elevated temperatures, preventing the formation of lumps or scorches that can compromise product quality.

Improved Physical and Dynamic Properties: By promoting a uniform cross-link network, TMTD(TT) contributes to enhancing the physical properties of vulcanized rubber, including tensile strength, modulus, hardness, and abrasion resistance. It also improves dynamic properties such as resilience and fatigue resistance, making rubber products more durable and functional.

Synergistic Effects with Other Accelerators: TMTD(TT) can be used in combination with other accelerators, such as thiazoles or sulfenamides, to achieve a synergistic effect that optimizes the vulcanization process. This approach can result in a more controlled cure rate, improved dispersion of sulfur, and better balance between scorch resistance and cure speed, tailored to specific application requirements.

Compatibility with a Range of Rubber Types: TMTD(TT) is versatile and compatible with various rubber polymers, including natural rubber (NR), styrene-butadiene rubber (SBR), butadiene rubber (BR), and nitrile rubber (NBR), among others. This makes it suitable for a wide array of applications in the tire, automotive, construction, and industrial rubber goods industries.

Processability Enhancements: The use of TMTD(TT) can improve the processability of rubber compounds by enhancing the dispersion of fillers, pigments, and other additives. This leads to better flow properties, which are beneficial during extrusion, calendering, and molding processes, contributing to higher quality and consistency in the final products.

Environmental and Safety Considerations: While TMTD(TT) is an effective accelerator, it requires careful handling due to its potential health and environmental impacts. Appropriate safety measures must be followed during storage, handling, and disposal to minimize risks. There is also a focus on developing and implementing safer alternatives or reducing the use of accelerators to align with sustainability goals.

In summary, TMTD(TT) is a crucial component in rubber manufacturing due to its effectiveness in accelerating vulcanization, providing scorch resistance, improving physical properties, and working in synergy with other accelerators. Its compatibility with various rubber types and its contribution to process efficiency make it a widely adopted accelerator across the rubber industry. However, its use must be balanced with considerations for environmental safety and health.