Promoter TMTM and Promoter TMTD Usage

- Mingpai

- 2024-06-07 13:57:09

Promoters TMTM and TMTD are both sulfur-containing chemicals used as accelerators or promoters in the vulcanization (curing) process of rubber compounds, particularly in the production of tires and various industrial rubber goods. Here's a brief on their usage:

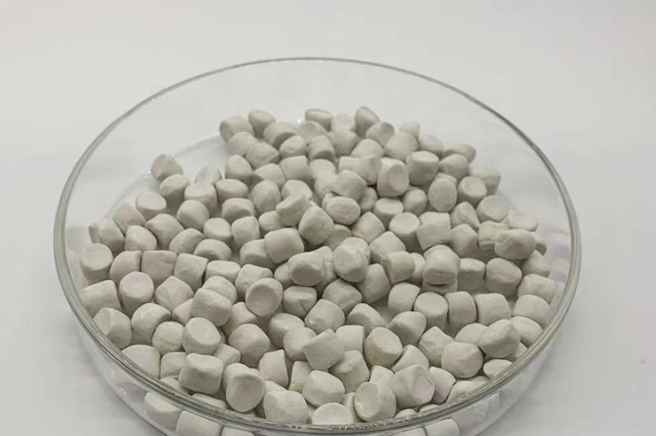

Promoter TMTD (Tetramethylthiuram Disulfide):

- Function: TMTD acts as a highly effective accelerator, speeding up the cross-linking process between rubber polymers during vulcanization. It belongs to the class of thiurams, known for their rapid acceleration properties.

- Characteristics: It provides a relatively short scorch time (the time before the mixture starts to cure prematurely) and promotes fast curing rates, making it suitable for quick-cure applications or where high-speed processing is desired.

Usage: TMTD is widely used in the manufacture of tires, rubber belts, hoses, footwear, and latex goods due to its ability to enhance physical properties such as tensile strength and modulus. However, due to concerns over potential health and environmental impacts, there has been a shift towards finding alternatives, like TBzTD, which are considered less harmful.

Promoter TMTM (Tetramethylthiuram Monosulfide):

- Function: TMTM, while still an accelerator, is considered milder in its action compared to TMTD. It belongs to the same chemical family but with different sulfuration characteristics.

- Characteristics: TMTM typically offers a longer scorch time, which means it delays the onset of vulcanization, allowing for better processing and mixing times without premature curing (scorching). It provides a more controlled cure, which can be beneficial in certain formulations or processes requiring slower reactions.

- Usage: Due to its more controlled curing profile, TMTM finds application in complex rubber compounds where a more gradual and uniform vulcanization process is preferred. It is used in the production of technical rubber goods, wire and cable insulation, and some specialized rubber products where a fine balance between processing time and final product properties is crucial.

Both TMTD and TMTM play a significant part in optimizing the efficiency of the vulcanization process, with TMTD favored for its fast action and TMTM for its controlled and delayed curing properties. The choice between the two depends on the specific requirements of the rubber compound being processed and the manufacturing conditions.